Mr. Johannes Vizethum, Founder | Advisory Allies GbR

We design & operate Smart Technologies for Industry 4.0 based on deep insights in AI, IIoT, BigData and Cognitive AR/VR.

Script of Interview

Interviewee Mr. Johannes Vizethum (JV)

Position Founder

Company name Advisory Allies GbR

Company website URL https://advisoryallies.com/

Interviewer John D. Evans, CFA (JE)

Interview conducted on 26th August 2020

About Johannes Vizethum

JE: Take two. Okay. So let us start off by you giving the viewers a brief personal overview of yourself where you live where you grew up, and a brief professional overview, where you studied and what you did before Advisory Allies.

JV: My name is Johannes Vizethum, I’m glad to have this interview today and to have the opportunity to present myself my background, my company, and the context what we do in the Sino German or European relationship and specifically technology. So, I grew up in Central Europe close to Frankfurt, Wiesbaden, a very scenic town. I studied at the Technical University of Darmstadt, one of the leading universities, technical universities in Central Europe, which is 20 miles south of Frankfurt. I do come out of a stable environment. I’m married for quite a while, more than 30 years. And I have two daughters. Unfortunately, I can’t speak Chinese because I do not have a Chinese girlfriend or a Chinese wife. I’m a sailor on top of this, so I always was traveling around the world. My background is a very professional – I started with Digital Equipment Corporation, DEC some time ago. Then I moved over to the telecom space coming up quite some time ago – British Telecom. When we talk about the mobile internet, I was one of the first people to work with Nokia and to make the mobile internet happen based on WAP, another technical term. So, I was always working at the front line many times generally, and now, I guess I am at the right place at the right time, when we talk about Industry 4.0 which we come to in this interview, later on. I am educated as a Master of Science in mechanical engineering and also as a Master of Business Admin. So, this is a very specific education combined two different degrees into one. And at this time, I am able to provide all these technical expertise and skills I have gained already in my study in my recent activities.

JE: Very good, very good. Now, you’re still located in Frankfurt, or Wiesbaden, very close to there. You travel a lot, I think, to China. Is that true? And do you travel to anywhere else? Or is it just Germany in China?

JV: I, as I said before, I was traveling throughout Europe. So, I am very embedded in business relationships in Europe, also into activities I still have in the Silicon Valley. So, it’s not China only. But coming from history, I was when I think back, I was starting my China initiatives maybe 13 or 14 years ago. So, then China was very, very different. Imagine we did not have a term Industry 4.0, we did not talk about what we talk about today in terms of technological collaboration. I was alone, I did not have an impressive business card. So, I started from scratch. And I started in Beijing, Haidian District, which was the only place and we did talk about internet and any kind of leading technology from China. So, I have a good history, insight and know what I talk about China. But, most recently, I focus on the Sino German, Sino European initiatives and technology management.

JE: Okay. Now we’re going to get into Advisory Allies in just one minute. But before we do that, I notice on your CV, you’re associated with a lot of other companies and entities. Pick one or

two others that that you are involved with, and are they related to Advisory Allies or what’s the connection to these other companies?

JV: Advisory Allies has been founded a couple of years ago, maybe six years ago. And the contractual commitments I have at this point came up earlier. So I have contractual commitments signed before and I give you two examples. I work with the leading R&D entities here in Central Europe. Fraunhofer is a good example and the German Research Institute of artificial intelligence as well. And around this, we have some other names. I’m closely related to Darmstadt which is the city where the European Space Agency is located. So, around this entity, we do have a lot of smaller companies I’m working with. All of these companies are very intensively working on the latest R&D, technology areas, artificial intelligence is just one example.

JE: Okay. So, going forward Advisory Allies is your prime business that you will look to develop all of these new projects with. Okay.

JV: This company is registered as I said a couple of years ago under a German civil law, so, everything had been formalized, but it was passive, because I did projects specifically in the Sino German context for other companies under the contractual commitments I had, and in the automotive space as well as in the telecom space. So, we had a real revenue stream already a couple of years ago between China and Germany. BMW is in a way my reference from this time and then we moved over when all these Industry 4.0 driven technology management and collaboration topics came up in the 2025 context. So German as the Chinese one road one belt program, then we move over and put it on the Advisory Allies platform to take it from there and to design these kind of collaborations we will be talking about in this interview later on.

About Advisory Allies

JE: Okay. So Advisory Allies, I believe legally is referred to as a GbR. So, there’s not specific shareholders. Are there other major participants in the company? Or are you the driving force?

JV: I’m the driving force. It’s owned by me. No shareholder as you said. What happens now is specifically in the entrepreneur and startup accelerator, incubator context, Fraunhofer ventures for example. I’m also connected to TechQuarter which is a leading fin tech accelerator here in Central Europe located in Frankfurt. And, and with all these startup entities and startup constellations we are discussing how to collaborate and how to extend Advisory Allies activities. Also moving into AG is another term, German civil law term and maybe into an Incorporated, which is a GmbH. entity.

JE: Okay, fair enough. I know about those. Now, so it’s like the Advisory Allies is going to create an ecosystem of associated companies to work with to develop the projects as opposed to hiring a lot of people in house itself.

JV: Right – this is specifically driven based on the Sino German partnerships design. It is not needed to hire many people or to code internally or to provide any technical expertise. What we do is we provide the platform for all the technology R&D driven contributors into projects and Advisory Allies is the leading force in terms of how to form this kind of agile team on the European side, as well as on the Chinese side, to make this technology management platform and collaboration platform successful. Though this is a very new way to design an open partnership – constellation, to work on the project side as well as on the technology management side.

JE: So, therefore, as you’ve described, it is your role personally and Advisory Allies more sort of a business project management? Or do you also get into some of the technical technicalities in the in the actual project development?

JV: I tell you what people expect from me, we have so many contactors or so called Project Management Managers drifting around specifically in the Sino German, context, but what I do is based on people giving me the responsibility. I give you an example – I most recently talked to not only in one region in China, but this is a very dominant project which will be appropriate for others as well. Ningbo east of Shanghai, they expect from me to set up a laboratory like environment as well as to design artificial intelligence driven and cognitive augmented reality projects — not only to design the use and business cases, but also to make it happen means to implement it. So, they give me a call on Saturday night, maybe local time. I am here my privacy, and they tell me: fix it. So, this is a very good example of what I do and what counterparts expect from me in terms of responsibility and commitment.

JE: Okay, so these sound very project driven, but will they also become sort of permanent relationships? Or will you be sort of a permanent ongoing consulting for these projects when the development has been finished.

JV: We have a specific unique approach: we start with demonstrators, very project driven. We select the technology partners wanting to show up locally in China, we provide the use and the business case. This can be software and/or a combination between software and hardware. An example: I’m talking with the one of the German leading camera companies here to provide a camera on a sensor basis, including a PC for a robotics use case. So, we provide software-hardware, we specify this use case, and we send it over to be installed in a lab or at an end customer/a local enterprise. Then this demonstrates a kind of standalone project on a paid basis. Then we demonstrate what we can do with it. We invite local companies, Chinese companies to understand the value chain, the benefits. In the second step these companies contribute to this kind of implementation And then we grow, and a revenue stream is initiated. In some cases, this procedure is assisted by a local bank here in Frankfurt. Once we have this constellation in place, we then build an umbrella with a joint venture like contractual commitment in a second step. So, you see, we move from a demonstrator set up to a compelling new kind of joint venture and technology collaboration. By the way, we do not talk about technology transfer anymore. We talk about a real technology collaboration with selected elements fitting into the picture and fitting into this kind of procedure under Chinese management, this is a very important element. We have a lot of Industry 4.0 studios and environments in Suzhou, for example, from KIT Karlsruhe. But this constellation is no more wanted, people want to have it under Chinese management. And when we have this constellation, then the government comes in for funding as well. So, we build up a kind of agile team consisting of Advisory Allies as a leading force. Then we have the R&D elements from here as a technology management element. Then we have local enterprises in different regions. At present, it’s not only in Ningbo it takes place Guangzhou as well. I work into the Guangzhou Robotics Innovation Center, located in Huangpu district. And we have the government included and influencers. Influencers in China in this context usually are universities, selected professors, associations in the Industry 4.0 space and any kind of industry bodies. So, we have a very complex environment to make a project successful. And this is the uniqueness we do provide.

JE: In my experience in China, local government, local government in particular, as opposed to Beijing, is very active in trying to develop new industries, particularly when you’re looking at new technologies. So, your customer for these this really new type of business, are they likely at first instance to be local governments or are they also just individual companies here in China?

JV: A very good question, as this shows the complexity in the procedure and to make a project successful at the end. We started to offer a piece of software – cognitive augmented reality as we name it – to improve manufacturing quality , a very important piece of technology to add value and benefits in the QA and the quality assurance space. We started offering a POC for a tier one supplier in the automotive space. For suspension, for power train for all these important components, also in the eCar space, and they told us we would like to design medium-term R&D driven collaboration with you, but we would not be able to fund it. So, this POC simply was too expensive. So, we were discussing quite a while and then they came up with a government funded entity, a strategy company, something in between a government entity and a research and development entity and then this entity was willing and is now able to fund the whole project as an additional component. This is a very typical example how the Chinese side proceeds: they go out and they take more parties on board, technology wise and funding wise. This is very interesting, will never be happening here in Central Europe, but this is how it works. Though we are very quickly moving ahead in having one of the first references in the Industry 4.0 this space in this region

JE: With all of the partners and ecosystems you have in Germany and putting these project teams together and then all of the different entities related to the customer, it sounds like a very large number of entities and complex situation to all put together.

JV: This is true, – we have a close look to the use cases which are relevant at this stage in China to provide a very concrete solution with associated terms and conditions. Though one of the key aspects is not to come the top-up but bottom- up. I give you an example from the artificial intelligence space. I’m invited from the Chinese government to speak since more than two years now. So, I’m a regular speaker at leading shows, exhibitions, conferences. My last conference was to 2019 in Beijing, ‘hidden champions’, very typical German conference and I was sitting on the panel. They invited me just because of one question. How do you upgrade the industry – upgrade is used as a Chinese term in this context . You should go out and take a look to a small, medium Chinese manufacturer. We talk about Industry 4.0, and Industry 4.0 means intelligent manufacturing, go out and look to what’s going on in these small medium Chinese manufacturing companies. They have so many issues to solve, they have a 3D printing machine standing in a corner, no one is able to use it and to integrate in the automation process accordingly. So many elements needed to be integrated to make best use of additional technology components – and we are able to provide these in different categories. So, in this constellation, you must be able to add clear benefits and to look into an existing value chain and also into an existing infrastructure. And then to add specific solution components, this is a way we are doing our business today.

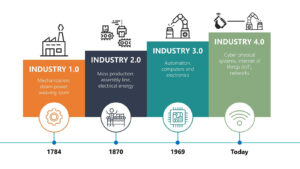

About Industry 4.0

JE: Now as you’ve defined just now, Industry 4.0 which is sort of the upgrading, automation, sophistication of manufacturing industry, it sounds like it could be applied to any sort of manufacturing industry. But is it focused in a few areas like is it is it just car companies or is it really a lot more broad than that?

JV: I’m educated as an engineer, I separate the industry we talk about industry generally and discrete manufacturing, manufacturing intelligent manufacturing is a headline, overall Industry 4.0 means intelligent manufacturing with all technology related elements. We have discrete manufacturing, and we have process in the chemical space. We have process manufacturing, we have we see, and we are facing major, major issues in the discrete manufacturing business, which means machinery automotive, and we are focused in this area right now. In the chemical health phase for example, we have other topics and issues to face but we see a bigger need right now in the discrete manufacturing space and this is why we talk with automotive companies. We talk with all kinds of industry and manufacturing companies in China.

JE: Okay. So, it sounds like auto is not the only industry but it’s an important part and maybe was one of the first ones and that would come into the connection with China and Germany because there’s a strong connection in the auto industry, isn’t there?

JV: Yes, it’s true. I will show you an example here which is quite heavy. We have this piece of a traction bar, can you see this, which is Chinese made and they provide this traction bar. This is a suspension and steering part, and this tract bar is manufactured in China by a Taiwanese company. And we would like, we are asked, specifically as a 3D printing context. This is what I mentioned before, how to build an ecosystem between among different Industry 4.0 elements. 3D printing is one of these elements, cyber physical system is another focus we are in. And in the 3D printing space, we tried to provide topology optimization. This means to make it, this piece I have shown you, to make it lighter, to reduce weight without losing strength, durability and functionality. This is a very good example. Geely auto, for example is talking to us, Advisory Allies, to form this midterm research and development driven collaboration with Continental Engineering Services, also located close to Frankfurt. So, we have a major tier one supplier here on the German central European side, we have a Chinese automaker, one of the biggest ones in China. Geely auto Volvo is a joint enterprise entry work into a midterm research and development driven technology collaborations. This is an example consisting of all the elements we are discussing in our interview.

JE: You mentioned before you made the comment that factories may have, for example, a 3D printer but they’re not using it. So, is it still very early stages in China, is a lot of training and education required to move this industry forward.

JV: This is a very good question because we talk about technology but, specifically on the government side, after my panel in December 2019 in Beijing, a lot of training and government education companies came to me and asked me: ‘how do you make it happen?’ We do not have the staff, we do not have commitment, people leaving companies jumping in between companies. So, they get to a company after six months they are leaving, good people. So, we do not have such stability on the staffing side to make these projects happen. And this is reason why we are now stepping into the vocational and the dual education space here we have a very good German model, specifically in the manufacturing space, we are able to mirror it and to make it happen in China. So, training, education related to the technology we are discussing here, is very important. It is a key factor to make a project successful. And so, we are thinking about how to provide online related training concepts, as well very closely related to this demonstrator and joint venture driven approach we discussed earlier in the interview.

JE: It sounds like this sort of training in education is very much focused at the company level and their employees. I mean, does this education and training have a place to go into a university or college curriculum

JV: Also, to get closer to people, this is a different generation. When we go into enterprises, we are facing specifically in the small medium enterprise space, and we have a lot of issues to fix when we talk to these people. But to reach a broader audience, it doesn’t make much more sense to step into university. And specifically, in the context of the, of one of my roles I have in the robotics phase, I mentioned the Guangdong Robotics Innovation Center set up in the Huangpu district in Guangzhou. This is a very good platform, and they are closely collaborating with universities also with government entities to make it happen. So, we are forming in the education space, we are forming this kind of agile team as well in the education space, very interesting. It’s the only place in on the planet where this is happening right now. And this is an open space. You can really design from scratch this kind of off collaboration and a different understanding. This is not Industry 4.0, this is simply education, to have a new conceptual approach. Very interesting and very motivated as well.

JE: So, with all of these new initiatives, requirements for training, etc., how long is it going to take before China really gets into a more mature area of Industry 4.0? Is these three years? Is these five years? Is it 10 years?

JV: I think, they have a good headline, when I talk to my Chinese friends, counterparts, companies, all the contributors, they tell me German technology in Chinese speed. So, let’s make a combination of both. I think China is looked to the face recognition space artificial intelligence driven, as they are so quickly looked to the e-commerce space, e-commerce, or e commerce related technology, China’s the number one place on the planet. It’s, in my eyes, not a Silicon Valley. It is not one of these heavyweights over there, it is Alibaba. And in the messaging ecosystem space, it is Tencent and look where Tencent has been. When I was in Shenzhen, the old headquarter, I know one of the Tencent founders, when I have been in Shenzhen, 14 years ago about, Tencent was, a 50 to 60 people company and look what Tencent is today. That shows you how quickly China is developing. It’s not looking to buildings, it is looking to economy and specific ways to make technology happen and to create this benefit and ecosystem. China is very strong in building ecosystems. So, when we look to an Industry 4.0 ecosystem, we must look to how to link it to, Industry 4.0 is a German brand and China is looking to Germany only when it comes to Industry 4.0 the only country they would like to design a deep collaboration with. And we have a very different approach, we are looking to sustainability, interoperability and some social impacts when we talk about technology and to coordinate Industry 4.0 technology elements like a digital assistant. We do not kick people out of company because of robotics, we try to educate people and to make it a digit and to make robots a digital assistant to the existing staff. China has a totally different approach. So, when you look to this impact, the social impact we have here in Central Europe, we have a totally different view on how to make technology happen. So, this might be taking a longer time to adopt, also standardization in the digital twin space. So, when you look to all these elements, you must look to make Industry 4.0 at the end successful. We have some elements, too, which need to take more time to bring it on to a global standard level or even social level and to sync up with the Chinese way and to Chinese speed. So, my view is it will be taking some time, maybe three to five years, you mentioned the right timeline. But, and to speed up, we and we need to make a revenue, we need to create a revenue stream. So, this is why we started as demonstrators and to transform it. So, we digitized it, we provided a kind of digitization transformation into a lab, which is funded by the government. And so, we get traction, we try to adapt Chinese speed, but around this picture we design we have some elements which take more time.

JE: Okay, now, I infer from your comments that within Europe, Germany is leading the Industry 4.0 drive. But in terms of competitive providers of this source, let’s ignore all of the political trade conflicts now, are there other areas in the world like in America? Do they have good developments of Industry 4.0 in America or is it really that unique to Germany?

JV: It is, look to the automotive space. So, the Rust Belt, we have so many issues in the rust belt, but this is a very powerful region in America. Talk about the Michigan-Ohio area. I know some people will, allow me to mention that I love my old classic Jeep, who comes from Toledo. So, I have a close relationship to the American automotive space.

JE: That’s Toledo, Ohio, not Toledo Spain, right?

JV: Yes, Toledo, Ohio. So, this is America, it is automotive, it’s history. But I am in touch with those companies and tier one suppliers. So, they would like to sell into China as well. So, this is still something I am facing. But I would say the transformation of the industry and digitization is one of the key elements which I’m dealing with, and, and other regions means in Europe, as I said previously, I’m well connected to different areas from Italy to Spain, France, even my Nokia history in the Scandinavian region. I’m still involved and in touch when it comes to make new technology approaches happen. So, it’s not necessarily only industry 4.0. And in Germany we have some elements and make best use of not coming from here not coming from Germany, Central Europe, but then you look to the process, pieces and how to work on the shop floor 4.0 to make, to look to value chains and look to key performance indicators to KPIs and to provide analytics on the shop floor and to work up from the shop floor 4.0 into a manufacturing execution system up to an ERP system and to make it an integrated approach, then Germany is still leading is the leading force implementing all these key elements into a process and value chain?

JE: So, when you’re in China now discussing these projects, who are you competing against? Do you have any specific competitors now for this same sort of project, that are coming in with a different group or consortium?

JV: Good question, as well, because we discuss what is unique with Advisory Allies. We have, in a way, competitors, sure everyone has a competitor. Big names, like Cap Gemini, Accenture, Ernst and Young, all the American companies, you mentioned American companies. So, we have, we must face that these companies have big representative offices with hundreds of people located in China and they’re running around in Chinese manufacturing entities, means this is a classic, in a way, traditional consultancy approach. We do not have this kind of approach. They are they have contractual commitments ongoing, and they step every day, they’re walking around the factory and providing analytics: this is what you can do better, you can save time and money when you reorganize your process, or you do it on the CAD or CAM level as well or even maybe in the 3D printing space. But this is, as I said, a traditional approach of providing ongoing consultancy. We are very focused on taking pieces they can adapt right away, technology pieces that can adapt right away and we also include different entities and influencing specifically influencers up to the government level, to develop the industry in one big step towards artificial intelligence, for example. So, we are not only analyzing, we do not analyze the process itself, we provide the elements of a total picture, and we are very quick in adding value in a specific area. In terms of implementing solutions, we do not analyze complex processes over weeks, and then we provide 100 pages document cost 50K or 100K US dollars. This is, I think in my eyes, a very traditional approach. To speed up, to be quicker, you must be able to identify an issue on the process level on the shop floor level, for example, and then coming up with a solution with a POC, which might be modified, and then to implement it, and then to look to the benefits and then to take it up from, to take it from there

and to add value. This is a different approach.

JE: When, and I’m not an insider to industry, I’ve been in finance, when I listened to what you say about your background, the engineering and AI firms around you in Germany, and then I can hear what you’ve just said now about basically big consulting firms, some of them which came out of the audit, they seem like very different organizations. They don’t seem like the organizations that are sort of building processes.

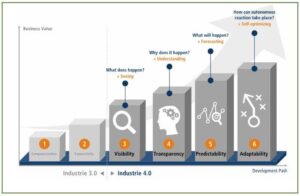

JV: Yes, very true. They think in value chains as well, we think in value chains as well. So, I think it benefits me as well. But the basic approach is to be quick. You mentioned where we’ll be in three to five years, how much time will it be taking to have Industry 4.0 like approaches implemented. So, this is exactly the context, when you look to the 2025 program and this is where we are working to, not to forget, this is a very important aspect. We understand very well this building, we have key strategic technology, AI and cognitive AR, augmented reality as an example. Then we have enabling technologies. Columns like this column says as we discussed earlier in the interview, 3D printing plus server physical system and then we have basic infrastructure elements to make it happen which are IoT, industry IoT, we have big data, and we have sensor level for example. So, I give an example how we how we how we approach. We look to a machine, or we look to an integrated machine as a couple of machines. Then we look to which sensors do you have, we add sensors, specific sensors, camera, I mentioned this camera sensor for example, and then we look about what can we take out of a machine in terms of more data, real time data, talk about real time data. How can we move to the next level; not just look to health management what’s happening here from a statistical point of view, regression statistics is in place in China. So, we have competitors providing regressions, statistical based analytics, but this is not what the government wants to see, they want not just to see a threshold-based approach. A temperature conductor, when the temperature reads and system reacts, temperatures too high, we have an alarm, this is old stuff. What they would like to see is how to mix sensor-regression space, two sticks, with a piece of artificial intelligence base added value. And you must be able to look into a machine and to add sensors and then to move up from the program logical controllers’ space, up to a manufacturing execution system in an artificial intelligence predictive intelligence-based environment. So, where we are today, we are today in how to understand the process and what’s happening in a process. That’s a situation right now. And then we have statistics. And we look back and then we try to predict something. But this is not dynamic. This is not big data, how to make the best use of big data we have today. So, you must be able as an engineer to understand what’s going on in a milling machine or any kind of other machine and then you realize that it’s a very simple pragmatic approach. You add a piece of hardware, and then you add a simple piece of analytics, and you build up a value chain consisting of different pieces. Then you add value and benefits. This is a very interesting, very pragmatic and this is a major difference to the consultancy companies I mentioned before.

JE: Okay, you’ve given us a lot of detail and about the technology and the customers and stuff. Let’s just give a very simple overview of a project. You don’t have to mention any company’s name or things. But tell us what’s the timeline from when you first started discussing, to when you agreed to project, how many firms engineering firms in Germany are you working with? Is it a local government and one industry just the parameters of one particular thing so that people understand the business process?

JV: A kind of reference. So, as Industry 4.0 is a very new term, and the government looks into and investing into this approach. Referencing is on the way, and I give I mentioned, previously mentioned, 3D printing example. I can name Continental, because Continental is one of the tier one leaders in the 3D printing space. And we have the R&D driven collaboration with government funding. And this is a very typical approach to work with a leading automotive company. And we are happy to have this R&D midterm collaboration, it’s not just a project. Another example is, I think I indicated previously as well. Maybe a more typical approach, having all the elements and contributors we discussed here in this interview, we have a Chinese company, a tier one supplier in the automotive space. We have in Ningbo, I must name it because we are on a very successful way to discuss with the provincial governor as well as with the mayor of this nice city. He’s very well supporting us in this approach. So, a very high-level conversation, ongoing conversation I personally have under Advisory Allies. And we have the elements as I said: the enterprise, we have the element to set up a lab which is a different activity, but will we merge it into one activity demonstrated driven we have Fraunhofer included in the cognitive augmented reality space as one of the key technologies to teach a key technology of the 2025 program. And we build up an agile team right now and then the training aspect comes on top. How to make the local staff successful in using all of these technologies in a demonstrator context. So, this is very complex, and this shows the integrated role Advisory Allies plays which is a very, very typical project and we see in other regions same kind of approach. Interestingly, with second tier cities, we have we are on a way to step into Hefei. This is another automotive and Industry 4.0 region, very interesting, very dynamic, very well supported by the government in Hefei, in Anhui province. Then we have it in Suzhou. This is what I mentioned as well. We have an in the south. We have it in Guangzhou and not to forget Zhuhai who knows Zhuhai? Zhuhai, we have a very strong company in Zhuhai and Zhuhai is not the Silicon Valley of China, Shenzhen Nanshan district is. I have, by the way, I have an office in one of my partners who are in Shenzhen in Nanshan, so I’m very well connected to Nanshan. I’m very visible in Shenzhen. But now Zhuhai comes on top, in the cognitive augmented reality space, very much funded by the very good connections to the MIIT in Beijing and funded as well. So, you see, you should not only look to the tier one city, Shenzhen, Guangzhou, Shanghai and Beijing, you should also take your time to explore opportunity abroad and abroad means second tier cities. And this is what we do now very concretely.

JE: Okay, now you’ve given us a lot of information. I’m conscious, we’re approaching the one- hour point. So, I’d like to finish off with two final questions. My second last question is, you’ve not been able to travel to China here this year. So how has COVID19 impacted this? Has it put things on hold, or have you been able to progress things virtually?

JV: I do not like this question. But we are, indeed, we are facing a delay. Yeah, we, this is true, but it’s simple, but this is very typical Chinese we learned speed again and we put it on a different platform is what I do now. I give you two examples we are, I’m a judge. I’m most recently on the judge, one of the leading and entrepreneur and company startup competition sessions. HiCool, from brink.io, one of the leading German American European constellations in Silicon Valley, Berlin, Shanghai, and Beijing base. And I’m a judge in this competition, semifinal, and now we have the final in September in Beijing. And I am able to come to contribute online. We have two weeks ago, the semi-finals, 30 companies pitching. It works, unbelievable, it works, fantastic. I’m online, pitching companies online, we have a scoring system online, perfectly done. And we see each other, and we have a good conversation, and we talk about technology, we see gestures everything. So COVID is a delay, but we have channels and ways to communicate online, they work. In the project space, it is indeed more difficult.

Because when you sign POC and I mentioned the constellation previously, you must be sitting there. You must have this trusted relationship, you must shake hands and you must be able to build up to not only to build up but to finalize this trusted relationship in terms of a contractual commitment in a lunch context and in a dinner context and to have fun, and to talk about family and to talk about relationship, you know, the Chinese. This is not a different region, it’s a different planet when it comes to relationship. COVID indeed, makes it very difficult, difficult to sign contractual commitments on a very personal level and without a personal face to face conversation, it makes it really it makes it an issue to sign a contract, and this is why you have a delay.

JE: Okay, fair enough. My final comment question, just to close off with your professional long-term interests. You said China in this Industry 4.0 may be mature in three to five years. So, is that your time horizon? When the industry gets mature then you’ll say, okay, that’s enough, I’ll either go do something different or retire to Majorca. What’s your long-term plans?

JV: Good, funny, good. Well, in my age, as I said, I’m still married for quite some time. In my age and my age most counterparts from the European or German side I meet are relatively not old like me, but they are fat, tired. They have enough money, and they are on a way to get retired specifically in these sessions, conferences and hidden champion sessions. I’m very disappointed of my German friends and counterparts in my age, they come up on the stage and they are very, very calm, very established, no need to work. I have a startup mentality, I get traction, I’m very sporty. Facing challenges, this just keeps me alive. So, I’m not interested to go to Majorca. I’m an active sailor, I take the risk and I think I am a true explorer. So, this is very much needed. And this is why people invite me and people pay me to speak. It’s not my engineering expertise and skills, people like my approach and my mentality and my exploring attitude. This is what you need to have to go over as not to have a perfect presentation, you must face the unexpected. So, you must be an adventurer. Maybe you must be a sailor, hope the best and expect the worst, in terms of whether this is a typical term for sailors. So, this is me.

JE: Okay, thank you very much for that. Let’s close it off here.

End.